Effect of melting temperature of . During hot melt adhesive road marking application, this product can shorten paint sticking time and improve traffic efficiency. After the paint is cured, a non-stick coating is applied. - a layer of dirt forms on the surface to keep the marking clean.

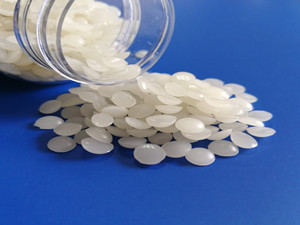

1. Polyethylene wax is widely used in road marking paint. It is used in hot melt road marking paint. Its main function is dispersant and leveling agent.

2. Requirements for polyethylene wax used in road marking paint must be free of paraffin and calcium powder and must be clean.

3. The melting temperature must also be above 100 degrees. Some road marking paint manufacturers require a melting temperature above 110. If it is too low, the road marking line will become soft, foamy, cracked and spotted. persistent.

4. The amount of oil should be small or no oil at all, while drying should be fast, adhesion should be strong, and the processing temperature should be above 180 degrees.

Road Marking Paint Wax Requirements: Polyethylene wax has better fluidity, makes the product more fluid and easier to construct, has better heat resistance, high hardness, and makes the paint surface hard, scratch and scratch resistant. Rolling, heat resistance; good wetting and dispersing action on titanium dioxide; good external slip, so that the paint film has good anti-fouling ability! Return to Sohu to see more

Post time: Jun-25-2023